Green power!

‘Green power’ is climbing up the priority ladder to such an extent nowadays that some predictions of fossil fuel costs (scorned at a few years ago), are coming home to roost.

We have chosen to be proactive and endeavour to be as reliant as possible on solar power as we possibly can. Our yacht carries a few more items such as additional solar panels and batteries which will surprise some and be talked down by others.

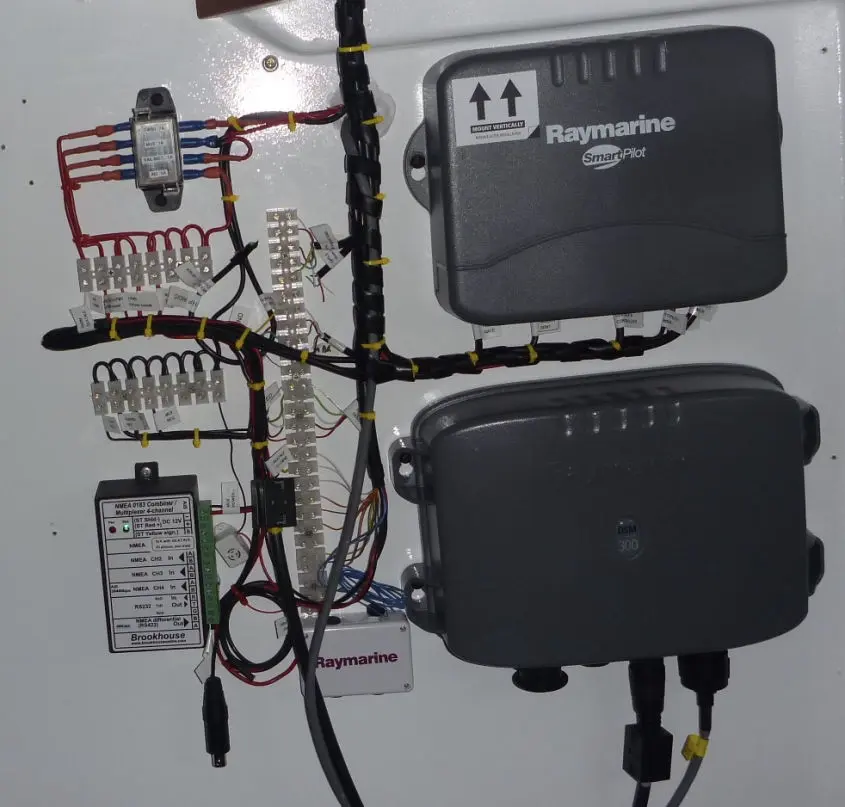

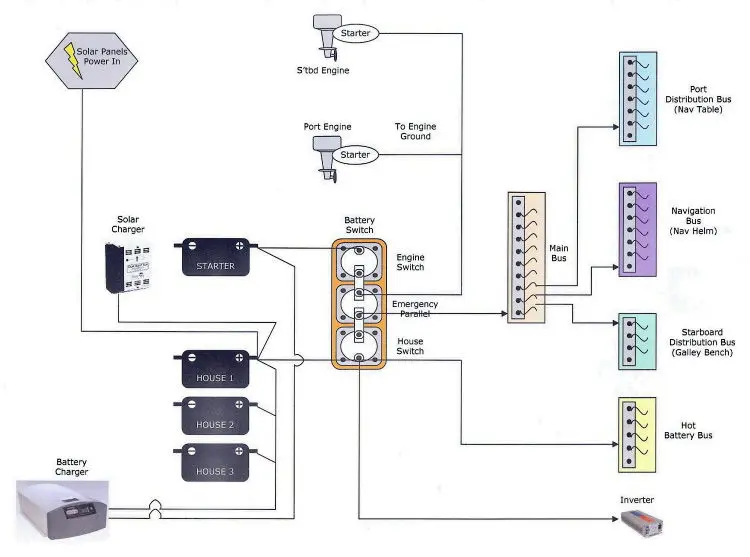

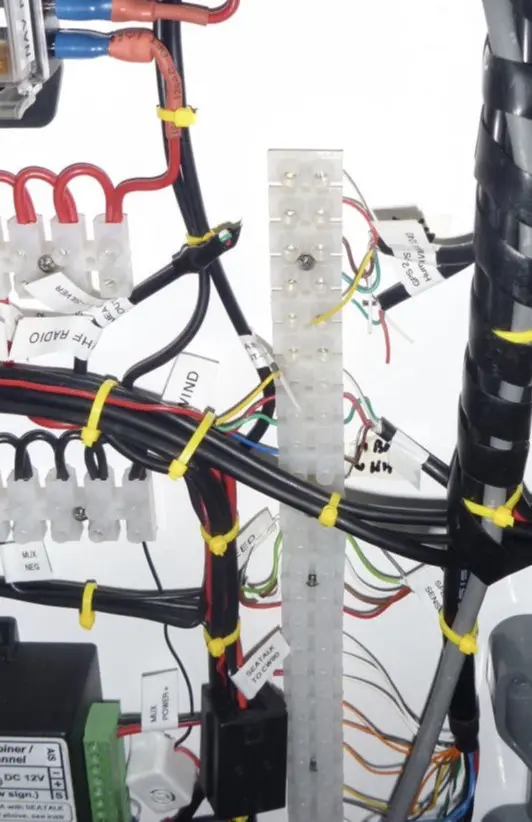

The electrical system has Solar Panels developing sufficient energy to charge three of the four Batteries to provide 12Vdc power to the vessel. Before embarking on its make-up a few things need to be clearly understood.

There is a reason that the Electrical Trade is a 4-year course in most countries and one can't read a 2-page document and be versed on all-things-electrical.

For the 'purists-in-electrical-know-how’, this may not be for you as there are phrases and words used here which may not be strictly correct in the your eyes.

We also strongly recommend that a qualified electrician be used in the connection of your vessels appliances. Your State legislation may require certification for systems over a certain voltage (or amperage) and some Insurance companies carry caviats against DIY Electrical.